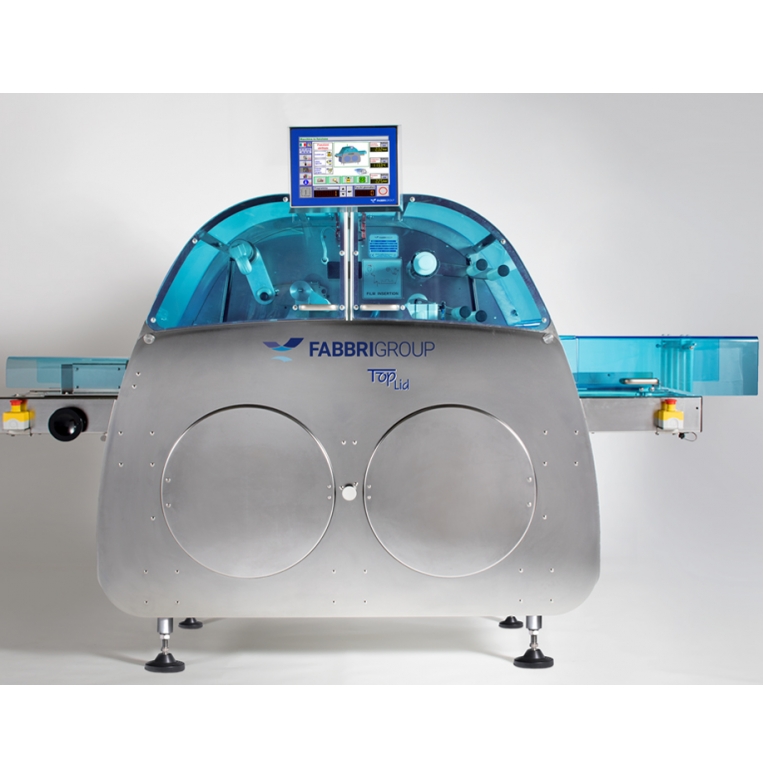

Gruppo Fabbri TOPLid

Tray Sealer

TOPLid is the ultra compact tray-sealer by Gruppo Fabbri, known for its performance and simplicity of use. Fully automatic, it is particularly suitable for the packaging of food products in a protective atmosphere, particularly meat, thanks to the patented gas exchange system. The compact size, high productivity and simplicity of use make this machine unique. The design of the punching tool has resulted in the extreme lightness of the components, making the format change accessible to everyone. Also available in a version completely made of steel, TOPLid can be used both in supermarket departments and large- and medium-sized packaging centres.

Unique characteristics include:

- extendable entry belt conveyors that support chaotic feeding

- gas exchange system that uses up to 50% less gas than conventional gas systems

- tooling that has been redesigned for extreme lightness as well as quick change (<5 mins). Operators follow screen prompts that minimise the chance of error and speeds up training so anyone can learn quickly.

- totally redeigned so that if specified the TopLid can be changed between single lane or double lane machine in a few seconds more than the normal tooling change. No longer do you need 2 machines for small and large trays or compromise on productivity.

- very compact and large range of exit options, ie, straight, exit 90 deg right or left, 180 deg exit (product comes back to the in-feed operator). The last option can significantly reduce labour requirement.

Main characteristics

- Small space, high speed TOPLid occupies approximately 1.6 m2 of surface area and offers a speed packaging up to 40 trays per minute in the double-line version. It is the only tray-sealer in the world to offer these benefits with such small dimensions.

- Patented gas exchange system: perfect mixture, always. Thanks to the innovative gas exchange system, TOPLid can handle mixtures with residual oxygen up to 0.3%, without resorting to expensive systems equipped with vacuum-gas pumps. Moreover, there is no need for special and expensive power systems in the presence of high percentages of oxygen. - Sporty or classic look? TOPLid is available in both blue safety guard and stainless steel safety guard versions, to give you the opportunity to always have the right machine in the right place.

- Format change: in less than 4 minutes! And in complete safety. The format change is managed by touch-screen monitors and operators can perform operations by following simple, step by step instructions. In addition, the positioning of the various parts is controlled by the machine at different times, effectively excluding the possibility of making errors. Great attention has been given to the operator at this delicate stage: the limbs of the staff are never in contact with the critical parts such as sealer tools and blades, so that each format change can take place in complete safety. Thanks to the tool lightness, the machine doesn’t need a mould change chariot.

- Ring road or highway: the choice is yours. TOPLid can be ordered with a double-line configuration, a solution that exploits the maximum potential of the machine. This configuration can be easily converted to the single-line version by simply changing the punching tool and the programme. In the same time that is needed to perform a format change, you will have a machine available that can package different types of trays at the most suitable speeds. Unique!

- Monitor touch-screen: more beautiful in colour. Simple and intuitive interface to control all machine functions with a simple touch. Everything, multi-lingual and coloured.

- Guaranteed sealing. TOPLid, in conjunction with the best performing film in the market, ensures excellent sealing even at maximum speed, guaranteeing the highest safety standards to clients. TOPLid provides the best performance with PE-Lid 22, a 5-layer high barrier film, specially developed for tray sealer machines by Gruppo Fabbri. Suitable for any tray, in every way.

- The automatic in-feed of TOPLid allows for the packaging of trays without any need for prepositioning or spacing at the entrance, typical of traversing bar machines.

- It can also handle the same format with different heights at the same time, thanks to its innovative tray-loading system. All accessible, all protected.

- TOPLid, like all the packaging machines of Gruppo Fabbri, features several access points to various mechanical parts, thanks to the semi-covers that can be opened, the two front panels and the exit safety guards This guarantees utmost simplicity and speed in performing operations of cleaning and regular maintenance.

- The panel containing the electric, electronic and pneumatic units has an IP54 degree of protection and is located at the rear of the machine, ensuring total protection.

- Protruding product, overflowing solution. TOPLid can package trays with protruding products, all those products that for reasons of presentation or management extend beyond the edge of the tray.

- Thanks to the dedicated optional feature, TOPLid can offer a protected atmosphere solution with an attractive fresh appearance. It is special also in this regard.

Optional devices:

- Motorized in-feed conveyors (1/2/4m) 1/2 rows.

- In-line exit roller and 90° (right/left) - 180° (right) motorized exit conveyors.

- Photocell for product exit control.

- Photocell for registered printed film.

- Gas mixer and gas analyzer kit.

- 1, 2, 4 cavities moulds.

- Protruding products.

- Reversible 1-2 rows TopLid version.

- Stainless steel covers.

- Motorized tray-turning exit belt.

- Server TCP/IP connection.

- Teleservice and other optional features.